Abstract: The tapping machine is a kind of equipment which is often used in machining. In the past, the tapping machine used artificial manual mode, low efficiency and low precision, can not meet the needs of contemporary efficient production, the current urgent need for a high efficiency, high precision automatic tapping technology.

The tapping machine is a kind of equipment that is often used in machining. In the past, the tapping machine used artificial manual mode, low efficiency and low precision, can not meet the needs of contemporary efficient production, the current urgent need for a high efficiency, high precision automatic tapping technology. The automatic tapping machine control system has been developed by using force ray servo system, touch screen and other devices. After debugging, it has been put into use. The whole system has high efficiency, high precision and strong reliability. Automatic tapping machine works on the touch screen to set the depth of teeth, tooth distance and speed and other tapping parameters.

First, the electric tapping machine requirements

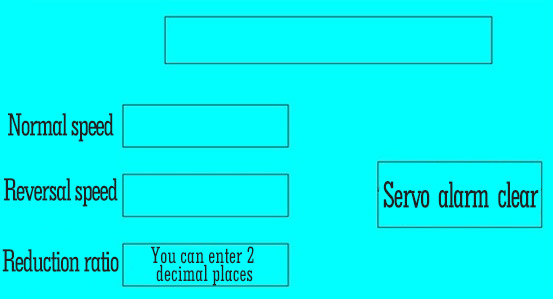

Interface three modes of operation: free mode, set the ring mode, depth mode, boot into the free mode screen, return to enter the mode selection painting. The operation handle is red and green two key switch as the direction switch, another small key switch as the limit switch

1. In free mode:

① motor speed = forward speed (or reverse speed) x speed ratio

② hold down the green switch, the motor is running, while holding down the green and red switch, the motor reversal (alone press the red switch no action)

③ When the rotation is on the screen, the free mode is displayed. In the reverse mode, the free mode is displayed.

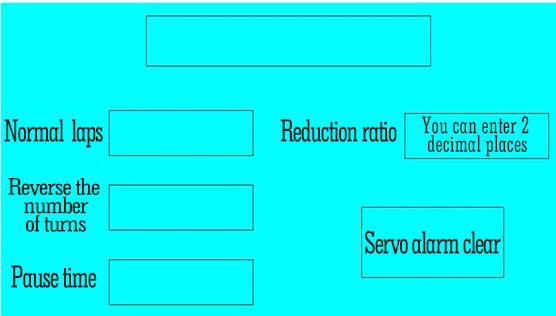

2. The circle mode:

① the number of revolutions of the motor = the number of revolutions (reverse turns) x reduction ratio

② hold down the red switch, automatically set the ring mode tapping (by setting the number of laps to complete the tapping out of the entire process), tapping the process of releasing the red switch, tapping process stop

③ forward rotation, the screen box shows the ring mode is running, reverse the show when the ring mode reversal, there are abnormal display servo alarm

④ Pause time input in milliseconds

3. The depth mode (this mode is done, this feature is not available on the screen)

① hold down the green switch, the motor is running, click the limit switch, the motor reversal, release the green switch motor stop

4. The motor appears abnormal display servo alarm, the screen can clear the alarm

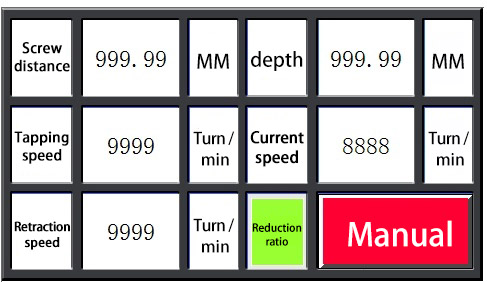

5. The touch screen main interface is as follows:

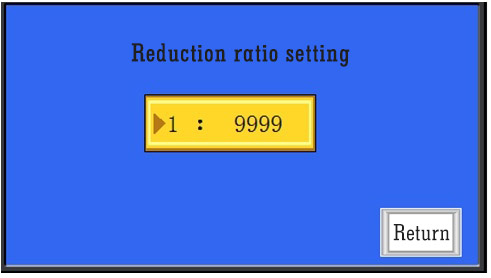

6.First set the depth of the tapping, screw set, tapping speed and wire speed (tapping speed set to positive, retract speed is set to negative), and then press the speed ratio button to enter the reduction ratio setting interface as follows:

A. After setting the speed reduction ratio of the gear reducer, press the return key.

B. In manual mode, press the left and right buttons on the handle to rotate the motor according to the set tapping / retraction speed;

C. In the automatic mode, press the trigger button on the handle, the motor will automatically perform a tapping and retracting action according to the set tapping depth.