Abstract: Xinlichuan Company has introduced a special servo control solution for the domestic heat sealing and cutting bag machine. It has successfully applied in the domestic bag making machine industry. The scheme adopts the force series B series AC synchronous servo drive, 130 series AC permanent magnet synchronous Servo motor, touch screen, PLC, inverter, inverter motor and other major components;

First ,The introduction

Xinli Chuan Company has launched a special servo control solution for the domestic heat sealing and cutting bag machine, and has successfully applied in the domestic bag making machine industry. The program adopts force series B series synchronous and synchronous servo drive, 130 series AC permanent magnet synchronous servo motor , Touch screen, PLC, inverter, inverter motor and other major components; according to the equipment requirements of the choice of inertia in the high-speed 130 series servo motor as the main sports institutions to ensure that the sealing and cutting bag machine in the frequent start load under the smooth movement And fast response, so that the servo motor of a feeding speed to meet the cutter up and down the operation of the time requirements. At the same time simplifies the mechanical mechanism, to solve the original mechanical equipment, low efficiency, low positioning accuracy, energy consumption, low level of automation, waste of materials and other shortcomings.

Second, the control principle

The entire equipment production process is divided into lifting knife, positioning, sealing and cutting three parts. The reciprocating motion of the heat-sealing knife and the cutter is controlled by the inverter-driven variable frequency motor. The bag length is controlled by the servo drive to control the feed roller. The photoelectric sensor (also called photoelectric eye), thermostat, proximity switch, For the measurement and control components, responsible for the time to judge and issue the control signal, so that the establishment of timing between the implementation of the device. PLC as the core of the carrier, responsible for the pulse signal transmission and a variety of control signal conversion and transmission, and ultimately control the operation of the implementing agencies and coordination. Touch screen as a man-machine interface for parameter settings and the entire machine running condition monitoring, through the touch screen can adjust the bag length, clear, reset, jog and other operations; can also display the bag length and the cumulative number of processed bags.

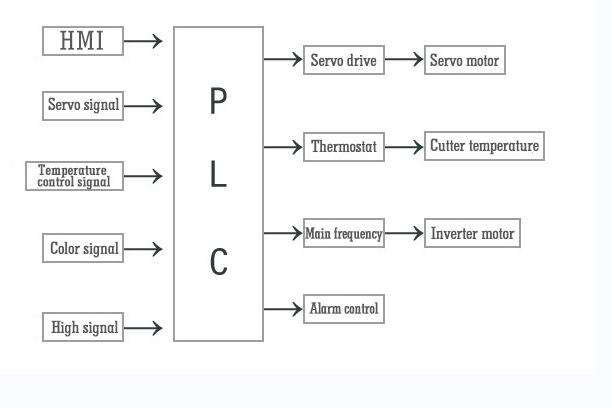

The following figure shows the heat sealing and cutting machine control block diagram:

Third, the work process

1. The system is powered on

Program initialization, the input bag length value, adjust the temperature meter, so that the temperature of the sealing knife to meet the needs of heat sealing (sealing knife temperature, should be based on the main motor speed set to the strong, Sealing knife temperature is low, will lead to plastic bag sealing is not strong if the knife knife temperature is high, will lead to plastic bag sealing at the burn, therefore, should be based on the main motor speed and sealing time to adjust); into the manual adjustment mode , Check the mechanical part, servo system, inverter, etc. can work properly, adjust the color standard photoelectric eye, so that it can affect the color change.

Click on the touch screen automatic operation button, the main inverter motor (1.5KW) work, through the mechanical link to drive the knife and cutter up and down reciprocating motion, the knife every time the upward movement, the servo signal on a turn, sent by the PLC pulse control servo motor (1.5kw) operation, the number of pulses determines the number of turns of the servo motor rotation, the frequency of the pulse determines the speed of the servo motor, the servo motor drives the feed roller through the belt, the servo motor must be cut to the cut Roller before the completion of positioning, when the cutter and the knife under the cut, the formation of plastic bags, when the number of bags reached the preset number or press the emergency stop button, after the end of the current production of plastic bags, cutters and knives Stop at high parking.

Bag machine generally has two kinds of sealing and cutting method: blank bag fixed length and cut the title seal, when the choice of blank bag fixed length when the color of the standard color photoelectric eye does not work, PLC program according to the length of the bag, mechanical transmission ratio, servo drive Electronic gear ratio, the number of lines of the servo motor encoder and the circumference of the feed roller, calculate the number of pulses required for positioning the servo system, and then drive the servo motor to drive the feed roller to send a certain length of plastic bag, When the selection of sealing and cutting, the process is as follows, the servo start signal conduction, servo motor in accordance with the PLC program pre-set the movement curve to accelerate the movement, constant speed movement, deceleration movement, low-speed chasing color, as shown in Figure 3 As shown, when the PLC receives the chase color signal, the servo motor is stopped immediately by the interruption. The general chasing color length of 10mm, and requires chasing color signal can only play a role in chasing color range, other areas need to shield out its interference signal. Chasing color cutting and debugging, the man-machine interface set the constant speed of the servo motor speed, first acceleration time, deceleration time set long, and then adjust the speed of chasing speed, as far as possible to improve the speed of slow recovery, , Accurate and accurate. Adjust the chasing color speed, and then adjust the acceleration time, deceleration time, as far as possible to shorten the acceleration and deceleration time to plastic bags and discharge roller does not occur relative sliding and chasing color prevail. PLC program in the chasing color cutting, the chase color signal count, three consecutive detection is not, PLC stop the motor running, and drive the alarm alarm. At the same time the PLC program on the batch count, when the batch reaches the early warning value, PLC driver alarm alarm.

Seeking speed curve

Fourth, the servo system

The servo system used in this machine adopts the latest digital signal processor DSP of TI's company as the core, and selects Mitsubishi's industrial grade intelligent power module (IPM), and the capacity of the selected IPM is the same as that of other domestic servo products with the same power Support a variety of communication methods, the standard fully isolated RS485 communication module, RS422 / RS485 optional; drive will be the location of the control, the use of a variety of communication methods, the standard fully isolated RS485 communication module, RS422 / RS485 optional; Speed control, torque control of these three control methods into one, and can be the dynamic control of the control mode, the use of more flexible and flexible; with over-speed protection, overcurrent, overload, overheating, the main power overvoltage, Abnormal, communication error, PID feedback signal anomalies and other protection and abnormal display, so that the control process at a glance. The motor is a three-phase permanent magnet synchronous servo motor with three times the overload capacity, 2500RPM rated speed, 2500-wire encoder resolution.

Mechanical parameters:

Mechanical transmission reduction ratio 1: 3

Cots diameter: 66mm

Accuracy requirements: bag length accuracy of less than 0.5mm, servo motor encoder pulse number of 2500P / R, after four times the frequency conversion, resolution accuracy of 10000p / r, that is, v = 360 ° / 10000 = 0.036 °, the motor output to The feed roller has a 3: 1 reduction ratio, the actual detection accuracy is: v roll = 360 ° / (10000 × 3) = 0.012 °, the corresponding bag length resolution accuracy: vl roll = πD × (0.012 ° / 360 °) = 207.24 x 0.000033 = 0.006839 mm

So the error itself is far less than 0.5mm, causing the positioning error is the real reason is due to the servo motor start and stop is not smooth enough, parking jitter, it is based on the starting speed of the servo motor to adjust the appropriate speed loop, Acceleration and deceleration time, the debugging process is as follows:

(A) the gain of the position loop is set to a lower value, and then gradually increase the gain of the speed loop to the maximum without generating abnormal sound and vibration.

(B) gradually reduce the speed loop gain value, while increasing the position loop gain. In the whole response without overshoot, no vibration under the premise of the position loop gain to the maximum.

(C) The speed loop integration time constant depends on the length of the positioning time, in the mechanical system is not vibration under the premise of minimizing this value.

(D) then fine-tune the position loop gain, speed loop gain, and integration time constant to find the optimum value.

(E) Properly adjust the position command primary filter time constant.

Five, summary

The heat sealing and cutting bag machine is based on the traditional old-fashioned equipment on the basis of the use of force Sichuan servo control system transformation, with improved efficiency; reduce energy consumption; improve yield; improve sealing and cutting accuracy; debugging convenient; smooth operation; Structure and other characteristics, with a higher technical content and more cost-effective for enterprises to create more benefits.