Industry background

A manipulator is an automatic operating device which can grasp, move or operate tools according to a fixed program, and can imitate some action functions of human hands and arms. It can replace the heavy labor of people to realize the mechanization and automation of production, can operate in harmful environment to protect personal safety, so it is widely used in machinery manufacturing, metallurgy, electronics, light industry and atomic energy sectors.

In today's life, with the rapid development of science and technology, the robot arm and the human arm is the biggest difference between flexibility and endurance. That is, the greatest advantage of the manipulator can do the same action repeatedly in the normal mechanical situation will never feel tired! Manipulator is a kind of high-tech automatic production equipment developed in recent decades, the accuracy of the work and the ability to complete the work in the environment. Industrial robot is an important branch of robot. As long as the repeatability is strong, the place which the Labor intensity is big may use the manipulator to replace the manual operation. Typical applications are injection molding machine, mold machine.

Field application

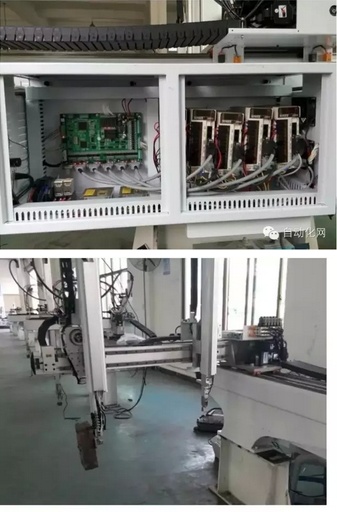

In the application system of manipulator, the control elements of manipulator include working order, arrival position, action time, motion speed, plus or minus speed and so on. Manipulator control is divided into point control and continuous trajectory control.

All-servo manipulator is the drive mechanism is driven by Servo Motor, that is, by multi-axis Servo control to achieve movement control, such as Bending Angle, X, Y, Z axis three-dimensional action by servo motor.